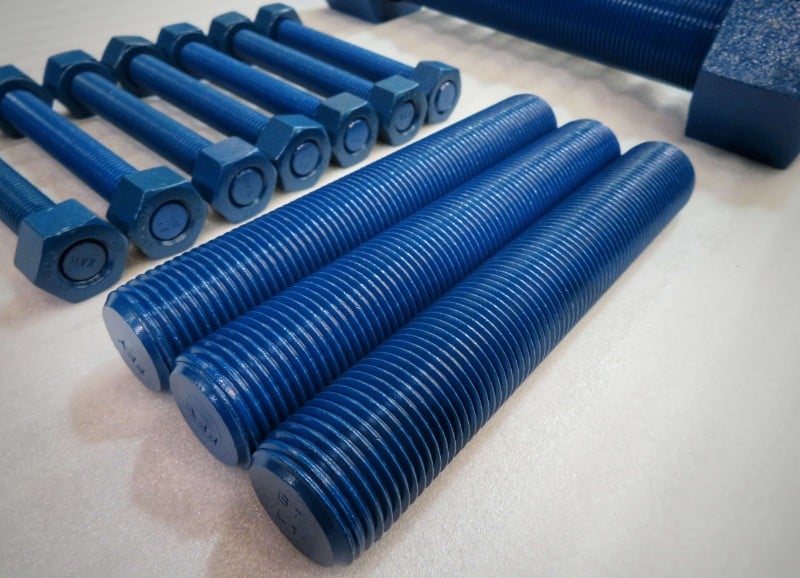

Fluoropolymers are synthetic polymers made from fluorine, carbon, and other elements. These materials have many qualities that make them good for coatings, and Fluoropolymer Coating is one type of coating used with this material. A fluoropolymer coating usually protects the surface underneath it by creating a barrier between it and the outside environment. Fluoropolymer coatings also tend to be very durable because they are made up of multiple layers, which helps keep them intact through wear and tear better than other types of coatings can do on their own

What is Fluoropolymer Coating?

Fluoropolymers are synthetic polymers made from fluorine. They’re used in various applications, such as food packaging and medical devices.

One type of fluoropolymer is the coating you see on your pots and pans; these coatings help prevent corrosion on metal surfaces.

Other types of coatings may be used for different purposes, including:

- Linings for cookware

- Anti-slip paints for stairs, handrails, and other areas where there is a risk of slip-and-fall accidents

Why Use Fluoropolymer Coatings?

Are you a manufacturer looking for an effective way to protect parts in your industry? Fluoropolymer coatings are one of the best ways to do this. You’ll find that fluoropolymer coatings can be used in a wide variety of industries and will provide many benefits for your business, including:

- Their high durability and chemical resistance properties make them ideal for protecting parts exposed to harsh environments, such as industrial settings. These properties also make it easy for employees who handle these parts regularly to avoid exposure to dangerous chemicals or materials.

- The wide range of colors available with fluoropolymers means they can match any aesthetic preference or visual style you have in mind when designing your product line. This also allows you more freedom when deciding how much coverage you want for each piece of equipment or machinery served by their coating application system (CAS).

Coatings over Compounds – Advantages of Coating It

When it comes to coating compounds, there are plenty of benefits that you can enjoy. For example, compounds are easy to apply and can be used on various surfaces. Compounds provide excellent adhesion to the surface as well as great coverage.

Coating compounds also have their drawbacks. For example, they tend to be thicker than paint and may require multiple coats before they look good enough. This can make them take longer than desired or cause problems with over-saturation if applied too quickly or carelessly. Another drawback is that not all paints work well when it comes to maintenance; some might need a special solvent instead, which means more money out of pocket!

Better Performance with Durable Fluoropolymer Coating

Fluoropolymer coatings are durable and can withstand high temperatures, so they’re a great choice for many different applications. They’re also non-stick, which means you’ll be able to use them with less effort in your manufacturing process.

These coatings are especially beneficial when protecting against corrosion and abrasion. Since they’re tough enough to withstand extreme heat and harsh chemicals, they allow your products to last longer without worrying about them breaking down over time due to excessive wear or tear (or even just normal wear).

Conclusion

The benefits of fluoropolymer coating are many. The different types of coatings offer a range of options for different applications. For this reason, choosing the right one for your project is important, not just settling for what’s available at your local hardware store.